Sept. 1, 2020 - DICA has rebranded its Linton line of products as LiftGuard magnetic sling protectors.

LiftGuard joined the DICA family of engineered products following the company’s acquisition of Linton Rigging Gear earlier this year.

LiftGuard sling protectors prevent damage to slings caused by contact with sharp or abrasive edges, corners, or protrusions from loads.

They also keep the sling away from other significant contact points during lifting operations.

Magnets in the Medium Duty, Heavy Duty, and Coil Edge protectors make placing the protectors simple, safe, and efficient.

As a bonus, LiftGuard protectors weigh 1/7 the weight of steel. They are available with optional Velcro straps to ensure proper sling placement, allowing the protectors to stay attached to the slings when the slings are removed from loads at higher elevations.

“We made the name change to highlight the phenomenal dual sling and load protection benefit LiftGuard provides,” said DICA CEO Kris Koberg, “All slings, especially synthetic web and round slings, can be damaged during lifting, and loads are susceptible to damage from chain and wire rope slings if they are not properly protected. Edge protection with sling use is critical in preventing sling failure and is an OSHA requirement and ASME standard,” Koberg explained. The applicable OSHA regulation is 29 CFR 1910.184(c)(9) and the ANSI standard is B30.9.

When using synthetic web slings, the capacity of Medium and Heavy Duty LiftGuard edge protectors is calculated at 12,500 psi/1” of sling width per protector. When using synthetic round slings, wire rope slings, or chain slings, LiftGuard product capacities are 12,500 psi of compressive strength per protector.

In addition to protecting against cuts and abrasion, LiftGuard sling protectors benefit sling capacity. The shape of each LiftGuard protector creates a D/d ratio of 5:1. This high D/d ratio lets slings be used at 75% to 90% of their capacity. Lower D/d ratios severely limit sling capacity and can lead to sling overload.

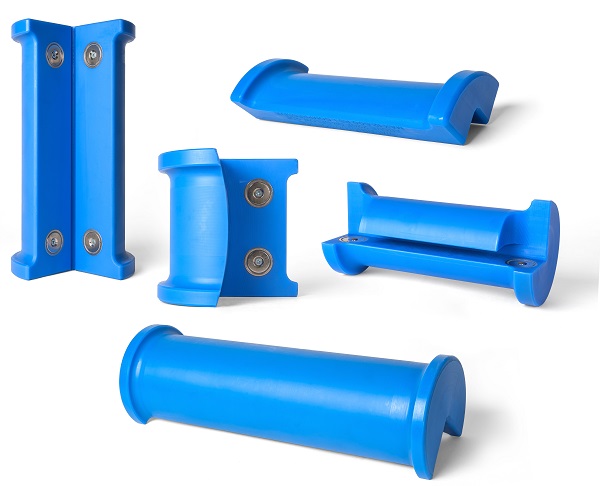

LiftGuard magnetic sling protectors come in Medium Duty and Heavy Duty models. Specialty Grooved units are designed for I-beams, and Coil units are available for lifting steel coils.

“Cut and damaged slings are the cause of many rigging related accidents. Using LiftGuard eliminates the need to use makeshift load or sling protection, or take unnecessary risks. We are excited to bring the LiftGuard product line, and all of its merits to the industries we serve,” said Koberg.